IPS e.Max Crowns

What are e.Max crowns? An e.Max crown is an all-ceramic dental restoration that is stronger than stacked porcelain. With e.Max, you can achieve a beautiful and cementable ceramic restoration without an underlying metal coping.

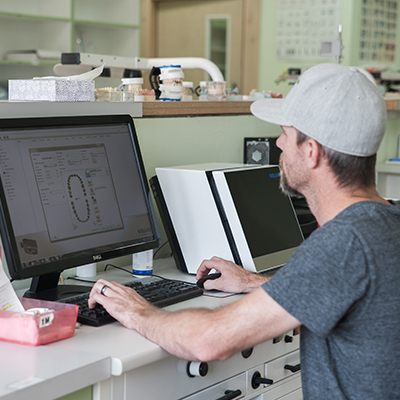

Stomadent Dental Lab creates quality, aesthetically pleasing e.Max dental crowns to help your dental practice succeed.

e.Max Crowns Material Qualities

- Lithium disilicate

- An all-ceramic material without a metal substructure

- Stronger than stacked porcelain

The dental restorative market started using lithium disilicate ceramics in 1988, before dental labs really started using CAD/CAM technology for fabricating crowns. At that time, a pressure casting technique created the all-ceramic crowns. Fast-forward to 2005 and the process started to incorporate the development of CAD/CAM technology in the dental lab industry. While the same monolithic lithium dioxide was used as e.Max crown material, the technique changed from pressure casting to milling. We’ve used this same technique to create e.Max crowns ever since.

Special Features of e.Max

- e.Max was introduced to the dental restorative market in 1988 using the pressure casting technique.

- e.Max processing was changed to CAD/CAM milling in 2005 to take advantage of technological advances.

- e.Max crowns are very aesthetically pleasing.

- The material used to create the e.Max crown possesses translucent and reflective properties that mimic and blend with neighboring natural teeth.

- e.Max may be fused to a stronger material, such as Zirconia, for added strength or when you need to mask dark areas.

When to Use e.Max Crowns

- Full coverage crowns

- Inlays

- Onlays

- Pressable ceramic veneers

e.Max Crown Preparations

- e.Max crown preparation is similar to full metal crowns

- Preparation for e.Max is less aggressive than for zirconia or porcelain-fused-to-metal crowns

- e.Max preserves the natural structure of the tooth

Color Choices

There is a broad selection of ingot shades available for e.Max dental crowns.

Delivery and Cementating e.Max Crowns

Cementation e.Max crowns are achieved by both bonded (adhesive) and mechanical retention.

Because cement is the weakest link, the tooth preparation itself should be well-designed and shaped allowing the best possible retention of the crown without cement. IPS e.Max restorations have two different possibilities for cementation: adhesive bonding and conventional cement.

Adhesive methods take advantage of chemically bonding the lithium disilicate restoration to the tooth preparation in addition to mechanical retention, yielding a crown that is less likely to come off over time.

Convention cementation allows for mechanical retention only and would make it easier to retrieve the restoration should you believe it may be necessary in the future (i.e. the possible need of endodontic treatment).

Average Lifespan

e.Max crowns typically last 10 to 15 years before fracturing.

How to Take Impressions for e.Max Crowns

There are several different ways to take impressions for e.Max crowns. These are the best ways to do so in order of preference for our dental lab:

- Impression-free chairside scans for a total digital workflow

- The crown preparation, as well as surrounding hard and soft tissue, is scanned at chairside and transferred digitally to the dental lab.

- Hybrid technology

- Utilizes scannable impression materials and impression trays

- Impressions and bite registration are individually scanned into STL files

- Images are later used to print 3D models in the dental lab

- Traditional polyvinyl siloxane impressions and bite registrations

Certification

Stomadent Dental Laboratory is a certified provider of IPS e.Max crown products.

- Our dental lab routinely undergoes training in order to ensure we are using e.Max as effectively and efficiently as possible.

Contact Stomadent Dental Laboratory today for free pickup in the Treasure Valley area. If you are located outside of this area, we will ship to you using two-day FedEx shipping.