What is 3D Printing?

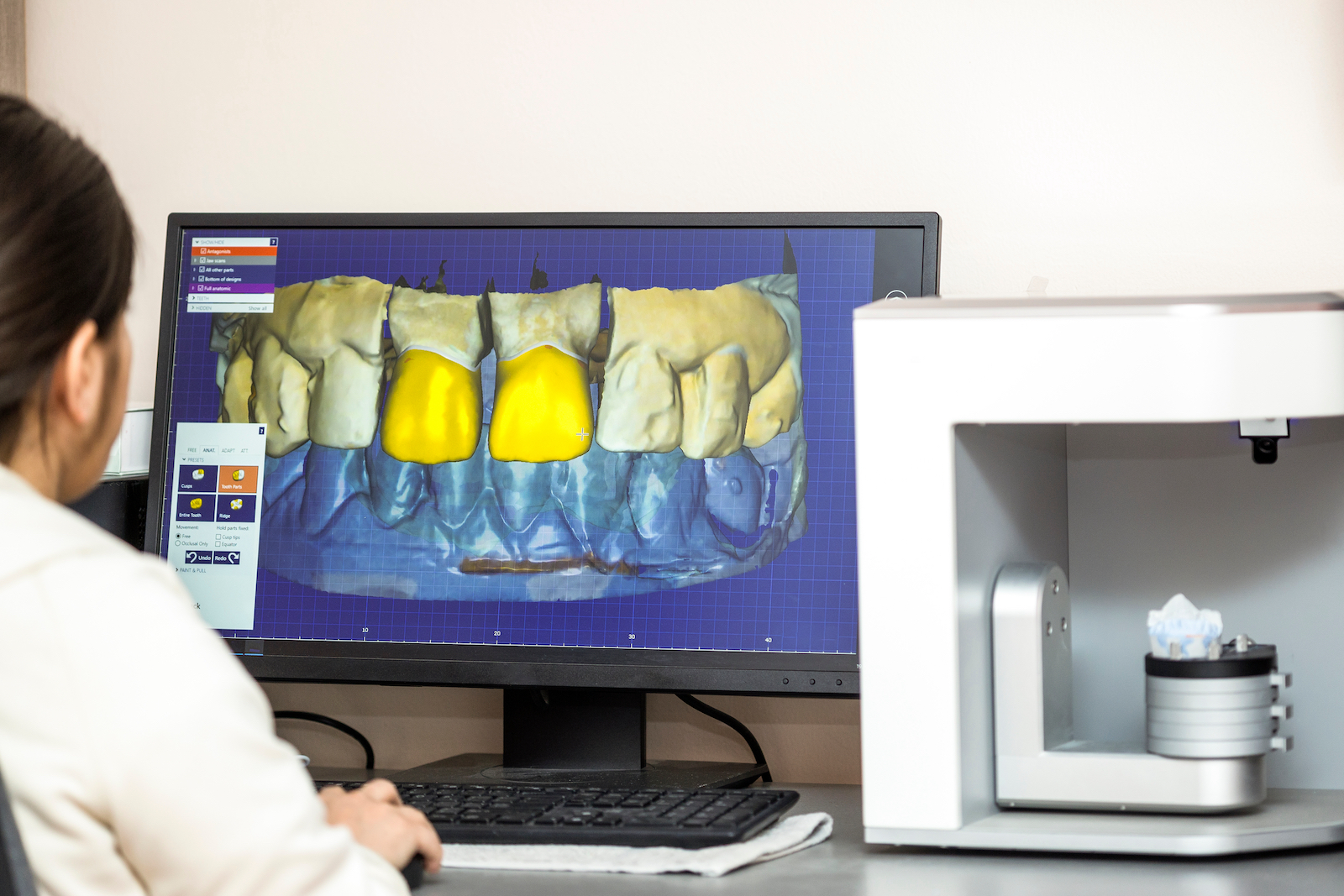

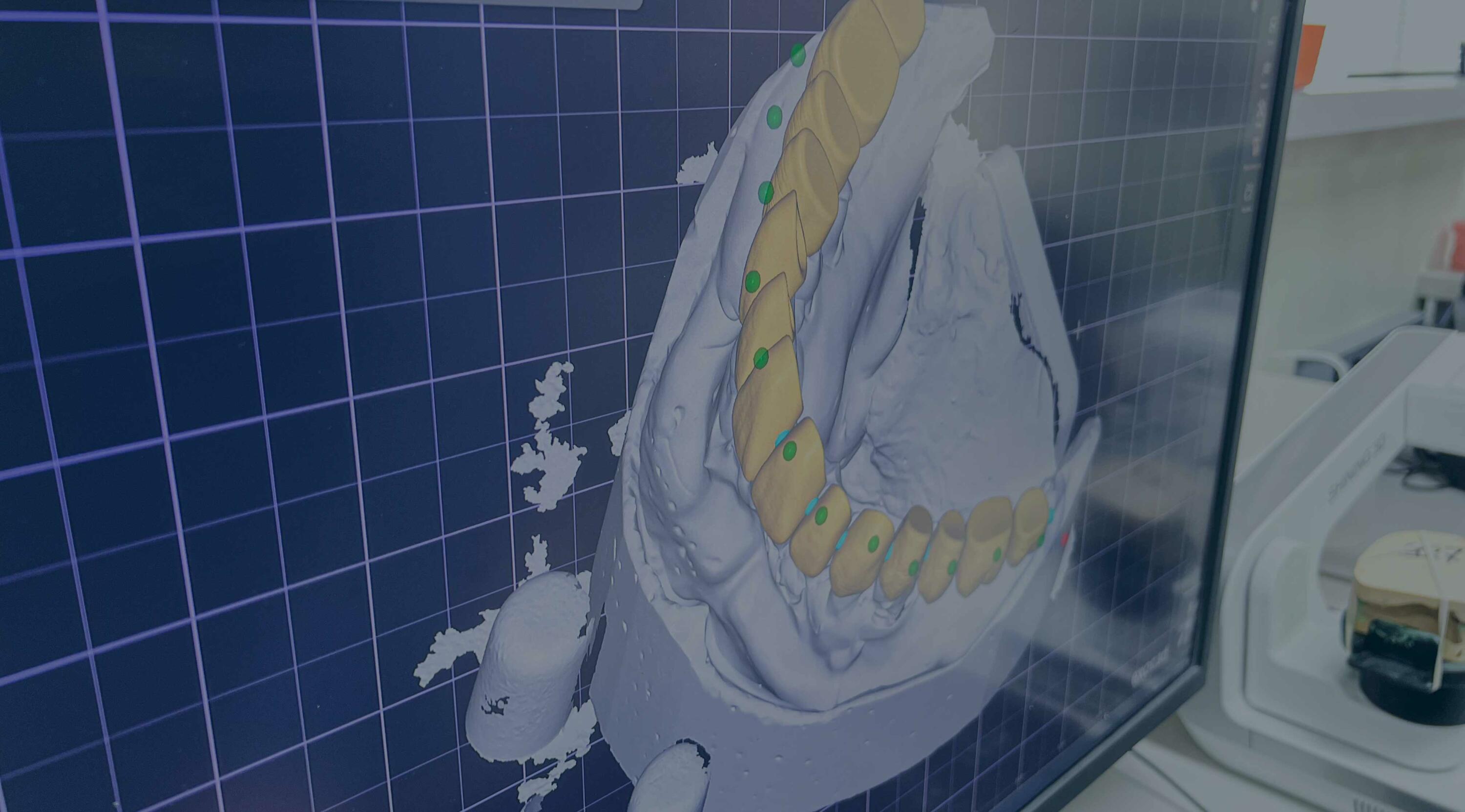

The process of digital 3D printing dental applications begins with a reservoir of raw resin in liquid form. 3D Printing is an additive manufacturing process whereby material is incrementally added onto a stationary plate to build the desired object dictated by computer-aided design software. Dental 3D Printing is used to accurately manufacture precisely fitting restorations and restorative components and surgical guides from various types of light-cured resins. Printed parts then undergo post-production processing by hand in order to join components to form a final dental appliance suitable for long-term use in the oral environment.

3D Printing Technology in Dentistry

Two different dental 3D printing technologies are currently commercially in use in most digital dental laboratories. Both work by selectively exposing liquid resin to a curing light source in order to form very thin layers of solidified material. These layers are then stacked upon one another to create the final 3-dimensional object. The main distinction between the two various 3D printers technologies centers around the type of light source used for resin solidification.

Stereolithography

First invented in the 1980s, stereolithography (SLA) uses an ultraviolet laser as its light source to trace each increment of material deposited, thereby solidifying and curing the resin while transforming it from a liquid to a solid. SLA is the most common resin dental 3D printing process in use and has become popular for its ability to produce high-accuracy, isotropic, and watertight appliance components with fine features and deliver a smooth, detailed finish.

Digital Light Projector

Digital Light Projector (DLP) technology employs a digital projector set up in a tight grid of square pixels to project emitted light, thereby curing the resin material. Digital light processing is very similar to SLA with one significant difference: where SLA machines use a laser beam to trace each layer, a DLP machine employs a projected light source that cures an entire layer of deposited resin. Since it is able to cure an entire layer all at once, the manufacturing process is much faster than SLA. DLP technology is most suited to those situations where production speed is key and a very fine level of detailed precision is not as overtly critical – temporary appliances, denture try-ins, study models, etc.

What is the Quality of 3D Printed Restorations?

With either technology, the accuracy and precision of the final dental restoration depend on many different factors, including the speed and overall quality of the 3D printer itself, the properties of the raw material, the CAD software used to translate the design to the manufacturing process, how the restoration is handled and processed post-manufacturing, and how well-calibrated and integrated all of these systems are with one another. Over the past few years, both the quality and precision of finished restorations produced by both light technologies have increased exponentially, allowing restorations to be printed with little to no chairside adjustments.

Printed restorations have the advantage of having no residual monomer to release and no polymerization shrinkage upon completion. This results in a hypoallergenic denture or other restoration types with superior fit. When compared with similar traditional acrylic monomer-based designs, dental 3D Printing is a much more accurate and efficient process that yields highly comfortable completed dental appliances, helping dental professionals maximize production.

Post-Manufacturing Processing

Similar to traditional processing methods, all dental 3D printer-produced restorations require further finishing by hand after manufacturing in order to be employed as a finished restoration. The printed parts are washed in solvents to remove any uncured resin before the object undergoes a final curing process. Most parts need to be cleared of their manufacturing sprues. Depending on the application, some assembly of components printed with different resins, such as denture baseplates with 3D printed or milled denture teeth, are often necessary to complete the restoration. Finally, finishing and progressive polishing are performed to make the appliance suitable for delivery to dental practices and use.

Dental Laboratory Applications for 3D Printing and Costs

While dental 3D Printing streamlines the manufacturing process, its up-front costs can be quite high. In addition, the light-cured resins employed in 3D Printing are often more expensive than chemically-cured resins. However, the additional cost of dental 3D Printing is often offset by lower labor and production costs per unit, making them affordable to dental professionals.

Valplast Flexible Partial Dentures

Valplast uses its own exclusive proprietary system to create Valplast flexible denture frameworks that feature flexible clasps via 3D Printing. Milled multi-layered polymethyl methacrylate (PMMA) denture teeth are generated separately to precisely marry with the flexible denture base, eliminating the need to manually trim stock denture teeth to fit between the patient’s abutment teeth. Using custom-milled teeth allows for dental production with a uniform appearance while saving valuable handling time.

Metal-free flexible Valplast partial dentures are available to dentists from Stomadent for the low cost of $385, complete with teeth. For additional flexible partial denture options and alternatives, see our Removable Fee Schedule.

Complete Dentures

3D printed denture baseplates and 3D printed teeth are each custom printed individually in their respective shades. Since the teeth are manufactured as one continuous unit, the teeth and baseplate components can be joined seamlessly with light-cured resin. Printing or milling denture teeth allows them to be manufactured to exactly fit the curvature of the arch for ideal denture stability and occlusion without the need to manually modify stock denture teeth.

Stomadent offers a variety of denture styles with various price points beginning at $218 for a single transitional/economy denture. Other styles made from improved resins are available at slightly higher price points, ranging up to $438 per denture for Premium Digital Dentures. Not all of our dentures are manufactured via 3D Printing or milling. Please see our Removable Denture Fee Schedule for additional information.

Printing Wax Try-Ins

Clinicians who prefer the added security of performing an in-office try-in before the denture is completed can request resin mock-up dental models of the final appliance to try into the patient’s mouth. This allows the dentist to check the bite and appearance before the final appliance is fabricated. If changes are desired, dental labs can modify the design within the software before fabrication of the final restoration. Printed try-ins are available at a nominal fee. Please see our Removable Fee Schedule for details.

3D Printing Lends Itself to the Production of Other Dental Appliances

Nightguards

Custom nightguards help protect the dentition and therapeutically ease tension placed upon the masticatory musculature in patients prone to nighttime grinding. They also are a great way to protect and prevent the destruction of dental implants and restorations when bruxism is an issue. Stomadent allows the dental professional to offer custom nightguards for bruxism patients starting at $165 each.

Custom Sports Mouthguards

Why subject your patient to avulsed teeth or a mouth injury on the sports field when protection is so readily available and affordable? A small investment in the prevention of trauma can avoid a lifetime of expensive and unplanned dental issues. We offer sports mouthguards to the dental professional for the low price of $83.

Custom Bleaching Trays

While many people use over-the-counter products to whiten teeth, every dental practice will say there is no substitute for well-fitting bleaching trays that ensure complete coverage and efficient use. Patients who use lab-processed bleaching trays find them more comfortable to wear and tend to use them more regularly than those who use one-size-fits-most trays. Stomadent offers 3D printed bleaching trays to the dental practitioner for $83 per tray.

Stomadent Dental Laboratory

Discover how Stomadent Dental Lab can support your practice’s success in the digital age. Stomadent has invested heavily in dental 3D printing technology so that dentists can offer their patients the best restorative solutions at a reasonable cost. Our dedicated team has made a commitment to ongoing training and the use of a fully automated workflow to ensure that your patient receives a comfortable fit without enduring numerous adjustments.

Why settle for anything less than the highest quality restoration or dental appliance possible? To take advantage of our new client trial offer or for additional information on any of our products, contact Stomadent Dental Lab at 208.888.1927.