Questions and Answers

By David Hudnall, DMD

In addition to electronic communication through our website and emails, Stomadent receives a variety of questions from our doctors. I had taken this opportunity to review these questions on the minds of some of our dental professionals. By sharing the answers to these questions, we hope you gain additional insight on subjects you had never considered before.

TABLE OF CONTENTS

Laboratory Processing Time

To calculate laboratory working time, please do not count the day the case is received in the lab nor the transportation time as part of the working time. As a general rule, straightforward cases will be processed within the time quoted under the “Production Schedule” heading on our fee schedules (available on our website). If you have a more complex case or require extra services, please allow additional processing time. Our lab manager can give you a better turnaround time estimate once the case is received and logged into our system.

Emailing Case Information

Where do I email digital photos of my case? Laboratory prescriptions and identified digital photographs to accompany your case may be directed to [email protected]. Digital photos are a great tool and allow the laboratory personnel to see the unique situation. Photos taken with shade tabs held next to the teeth aid in appropriate shading and allows for achieving a more esthetic result in the final restoration.

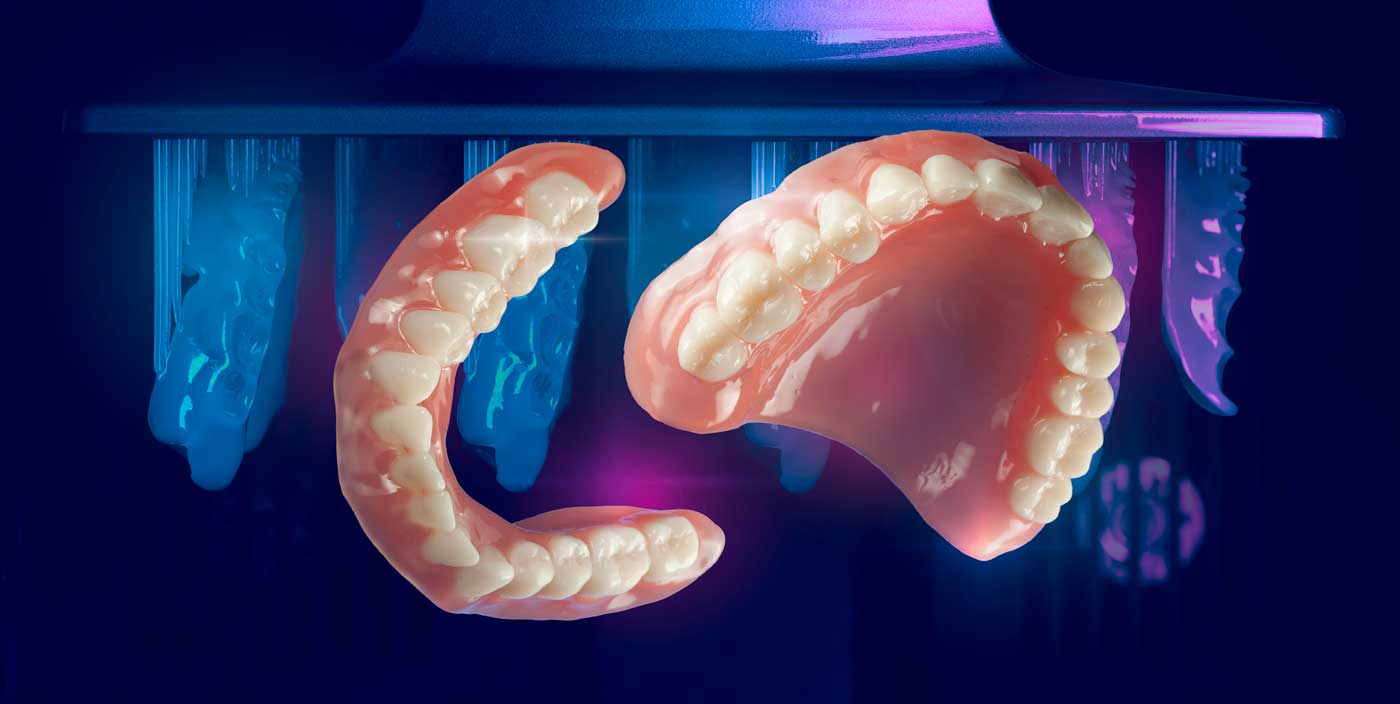

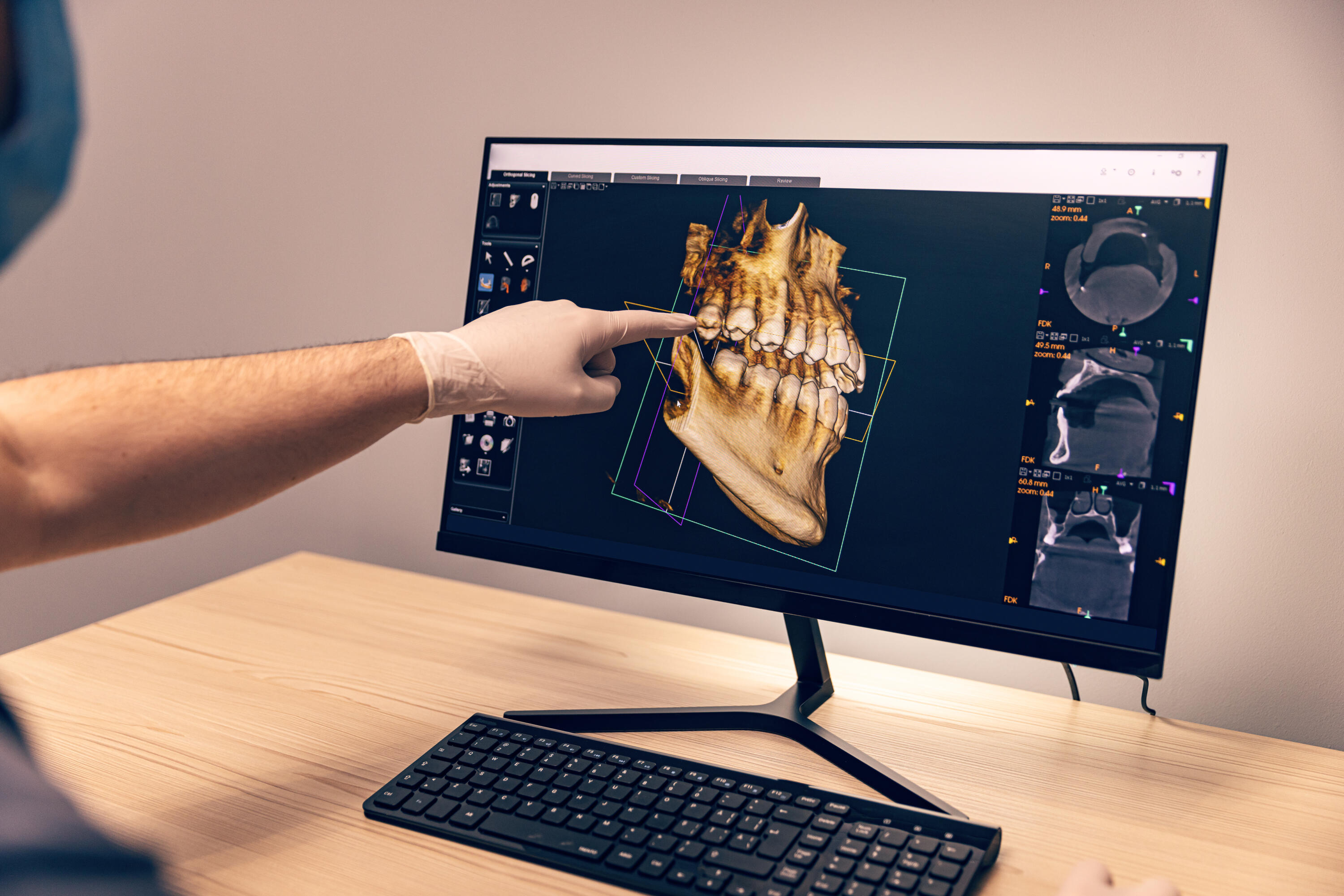

Digital Scanning Technology

How do I send digital impressions? If you take digital impressions using a chairside intraoral scanner or otherwise capture scanned data of physical impressions in your office, it is likely the data is captured into .STL files. Those files may be attached to an email along with case identifying information in the body of the email. The email may be directed to our dedicated email address for digital files at [email protected]. Like physical impressions, the digital data must be an accurate representation of the patient’s mouth. Don’t forget to scan the opposing arch with any opposing appliance in place if the treatment plan involves the patient continuing to wear the existing opposing partial or denture after the new appliance is fabricated.

Time Benefits Utilizing of CAD/CAM Technology

Did you know that making a titanium partial denture framework takes less time than casting methods? Titanium partial frameworks are milled from a solid plate of material, eliminating many of the labor-intensive steps necessary for traditional metal processing. The turnaround time for a basic cast metal framework is 7 working days; titanium is 4 days. You can reduce the lab turnaround time and have the benefit of a more precise-fitting metal framework requiring fewer adjustments by converting your case to CAD/CAM-milled Titanium.

Distal Extension Mandibular Partial Dentures

Valplast distal extension partials are not very functional because they flex when chewing. What would you recommend for the patient who is concerned about esthetics and doesn’t want to see metal? A great alternative option is a CAD/CAM-produced Zirlux Acetal framework partial denture. Zirlux Acetal is a semi-flexible resin material that is a step between a totally flexible Valplast partial and a rigid metal framework. And it is very esthetic thanks to the use of a tooth-colored framework and clasps that lie very close to the gingiva.

Can Stomadent Do an Implant Locator for a Valplast Partial Denture?

In theory, a Valplast partial denture could technically be made to work with an implant locator. However, it is not recommended. Because the Valplast material is flexible, a pickup impression will sacrifice the accuracy required to properly fabricate an implant locator. A more accurate choice for this application would be a Zirlux Acetal framework, a metal framework, or a hybrid partial consisting of metal framework with Valplast elements. This way, intimate fit with the implant locator can be assured.

Denture Base Allergies

My patient loves his new dentures but we’ve discovered that he is having an allergic reaction while wearing them, likely caused by monomer. The patient is happy with the appearance of the dentures and doesn’t want to start over with new dentures. What can be done? It is possible to rebase the dentures with a monomer-free denture base material to preserve the look of the dentures. To do this, take a wash reline impression inside of the existing dentures. The dentures can be re-processed using hypo-allergenic materials. The process requires two working days in the laboratory. Once rebased, the denture will fit like new. Remember there may be a slight but noticeable shade variation between the allergy-free denture base material compared to acrylic-based products.

Why Is Stomadent Your Laboratory of Choice?

Better, more clear information helps to bridge the physical separation of the dental laboratory from your dental office. We at Stomadent strive to be transparent with our information and procedures so that you will truly feel that Stomadent is a part of your dental team. When it comes to laboratory procedures and automation, you don’t know what you don’t know. With rapidly advancing technology, you may not know what new restorations are possible. Stomadent’s goal is to de-mystify laboratory processing and help your practice excel by providing the best restorative solutions for your patients in 2020 and beyond.