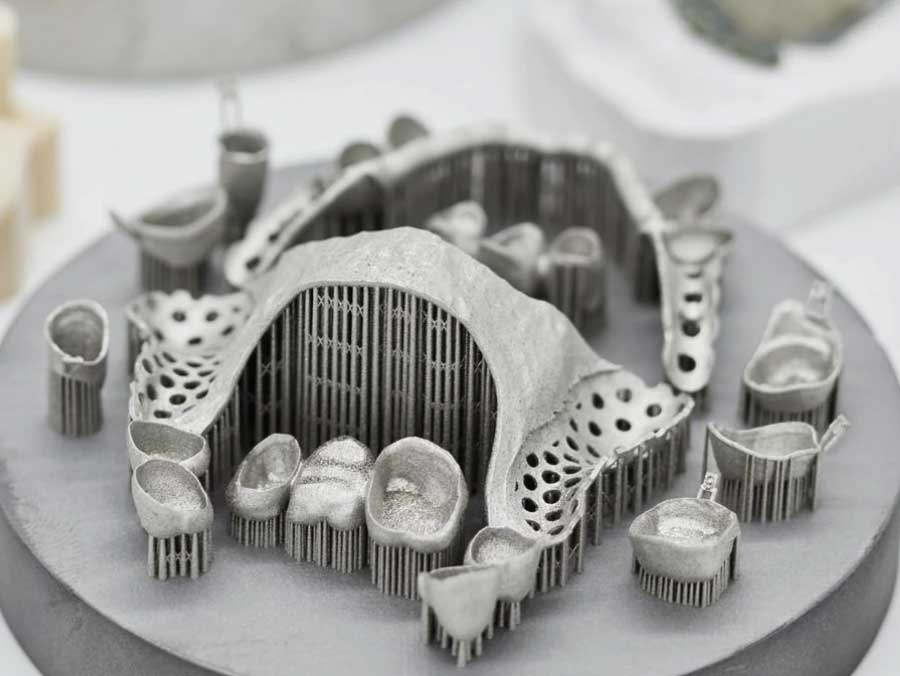

From the evolution of metal processing in dental technology, Stomadent Dental Lab proudly leads the transition from traditional casting and milling to advanced 3D printing. Leveraging state-of-the-art Selective Laser Melting (SLM) technology, we offer superior cobalt-chromium metal partials, redefining precision, affordability, and customization in dental prosthetics.

Advantages of 3D Printed Cr/Co over a Casting Method

Laser-printed chrome and cobalt partial denture frameworks offer several advantages over traditional cast frameworks. This modern manufacturing process is faster, reducing production time thanks to streamlined steps and eliminating the potential for human error associated with more manufacting steps and manual techniques. The precision of digital design ensures a more accurate fit, leading to fewer adjustments and greater patient comfort upon delivery. Additionally, the process uses fewer materials, which not only makes the frameworks lighter and more comfortable but also maintains their durability. Overall, these improvements lead to a more efficient, precise, and patient-friendly solution.

Thinner and Lighter for Enhanced Comfort

One of the standout features of laser-printed partial dentures is their thin and lightweight design, which significantly enhances wearer comfort.

Faster Turn-Around Time (4-5 Business Days)

Laser printing technology not only enhances the quality and fit of partial dentures but also significantly speeds up production time.

Increased Durability and Precision

The use of modern laser printing techniques in the manufacturing of chrome and cobalt partial dentures results in increased durability and precision.

Easier to Adjust

Adjustments on laser-printed chrome and cobalt partial dentures are easier and less time-consuming for dental professionals, enhancing overall patient satisfaction.

Minimal Chair-side Time

Laser-printed partial dentures require significantly less chairside time compared to traditional cast methods. This efficiency is primarily due to the streamlined digital process which eliminates several manual steps involved in the casting process.

Efficient Process

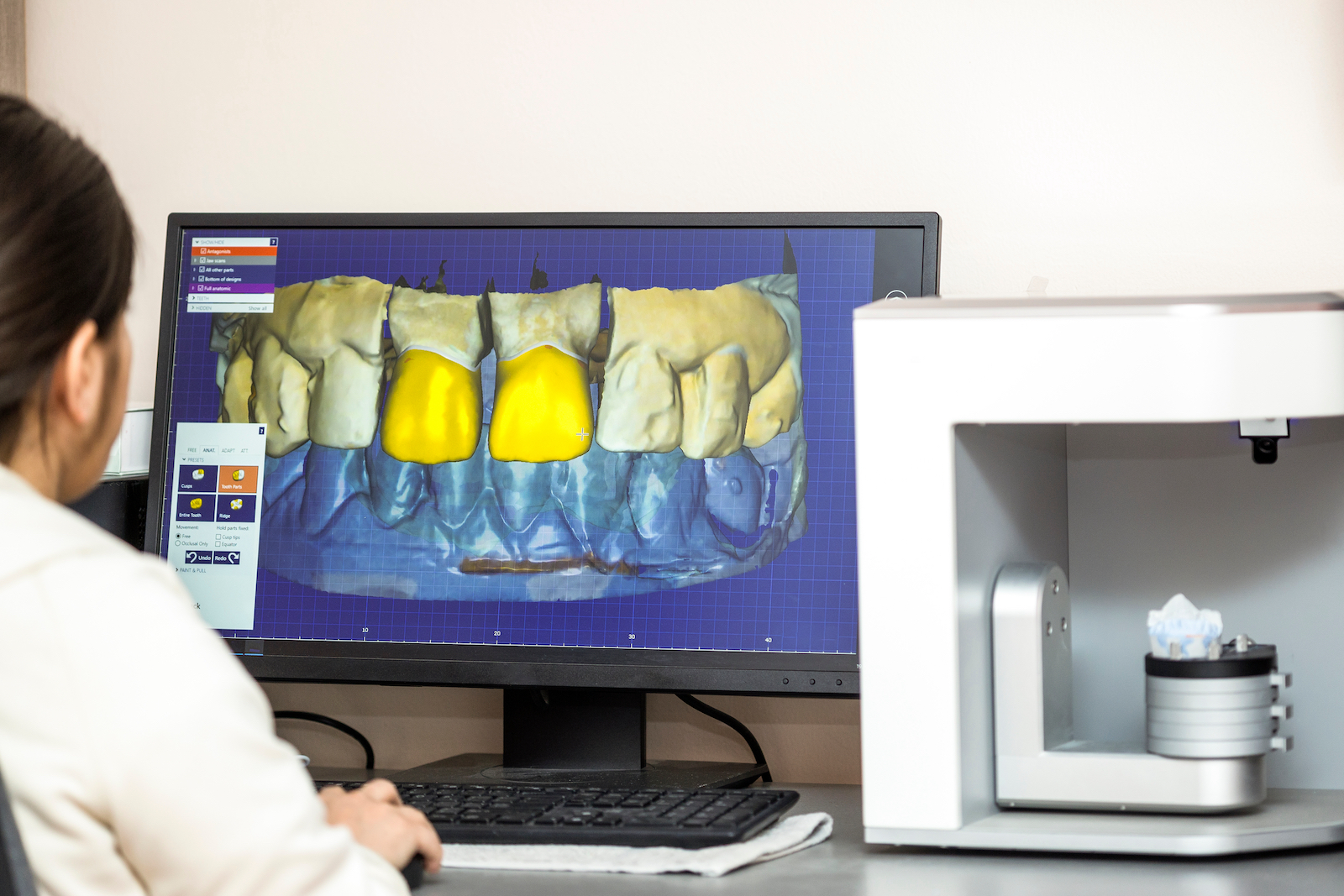

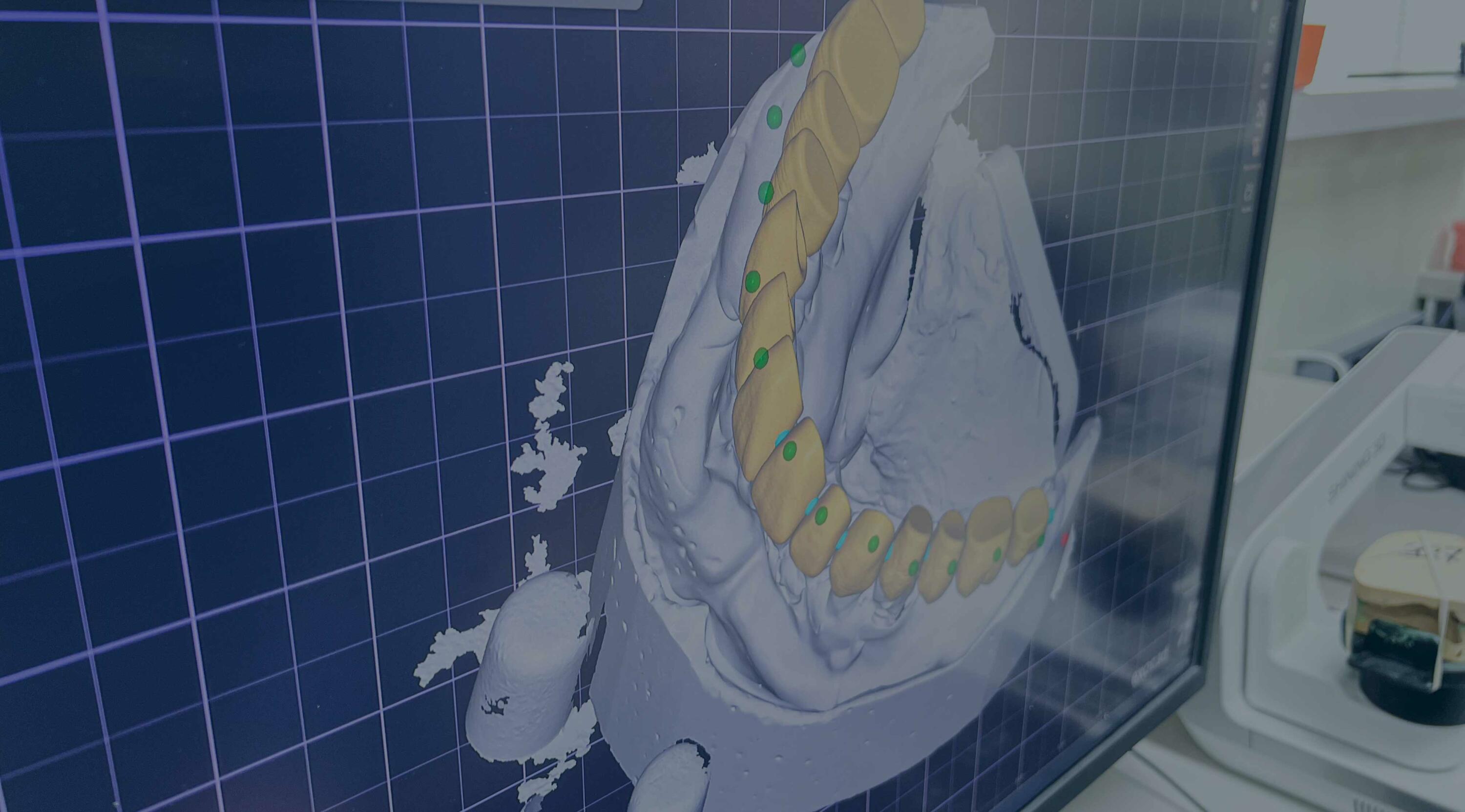

Design

Polish

Advance Your Practice with Cutting-Edge Dental Prosthetics

Explore the future of dental technology with Stomadent’s advanced 3D printed Cr/Co metal partials. Enhance your practice and patient satisfaction with our precision-engineered solutions. Contact us today to discover how Stomadent’s innovative dental solutions can transform your offerings.