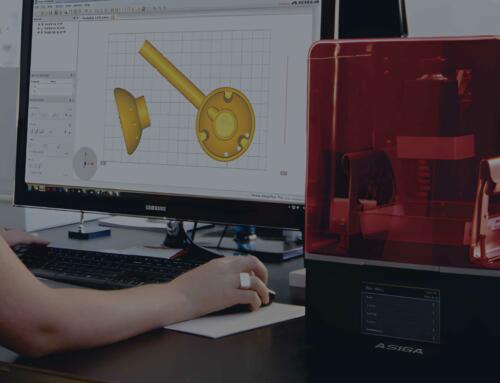

Roland Digital Printer Overview

- Acetal Resin Partials

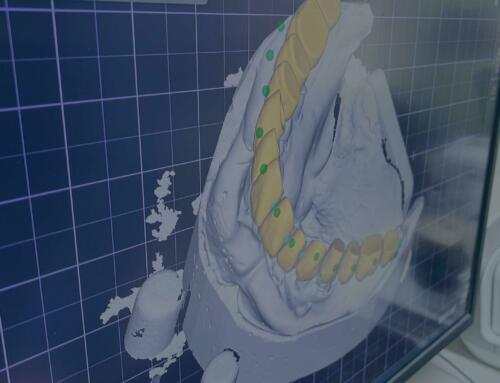

- Digital Dentures

- Denture Teeth Printing

This is our Roland Milling Machine. Stomadent actually has two of them. We use the Roland machine to mill Acetal Resin Partial Dentures. When we design the case, the digital design is transferred to the Roland machine. Using the digital instructions, the partial is milled from a solid disk of polymerized Acetal Resin. Very precise. It is a 5-axle machine. When it comes to the fit of the finished partial, it will be great. Four new burs are used to mill the partial framework to very fine detail.

Another advantage of milling the denture base is its uniformity. Because the denture isn’t waxed, the base can be of uniform thickness throughout the denture. If you want the base to be 2mm thick, it will be 2mm thick throughout the entire base. If you want the base to be 1.5mm thick because your patient requests a thinner than normal denture, you can request a thinner denture. We are able to mill the denture base to your requirements.

We are also able to mill denture teeth for incorporation into digital dentures. A huge plus to doing this is the material is very strong. It is made from multilayered PMMA (polymethyl methacrylate). The pod of PMMA also contains both the dentin and enamel layers for a realistic look. Milled teeth are combined with the digitally-printed denture base. The final result will be a very strong, high-quality digital denture that fits extremely well. Because the teeth are milled in groups of 3 or 4 teeth, a single tooth will not pop out by itself reducing repairs.